Description

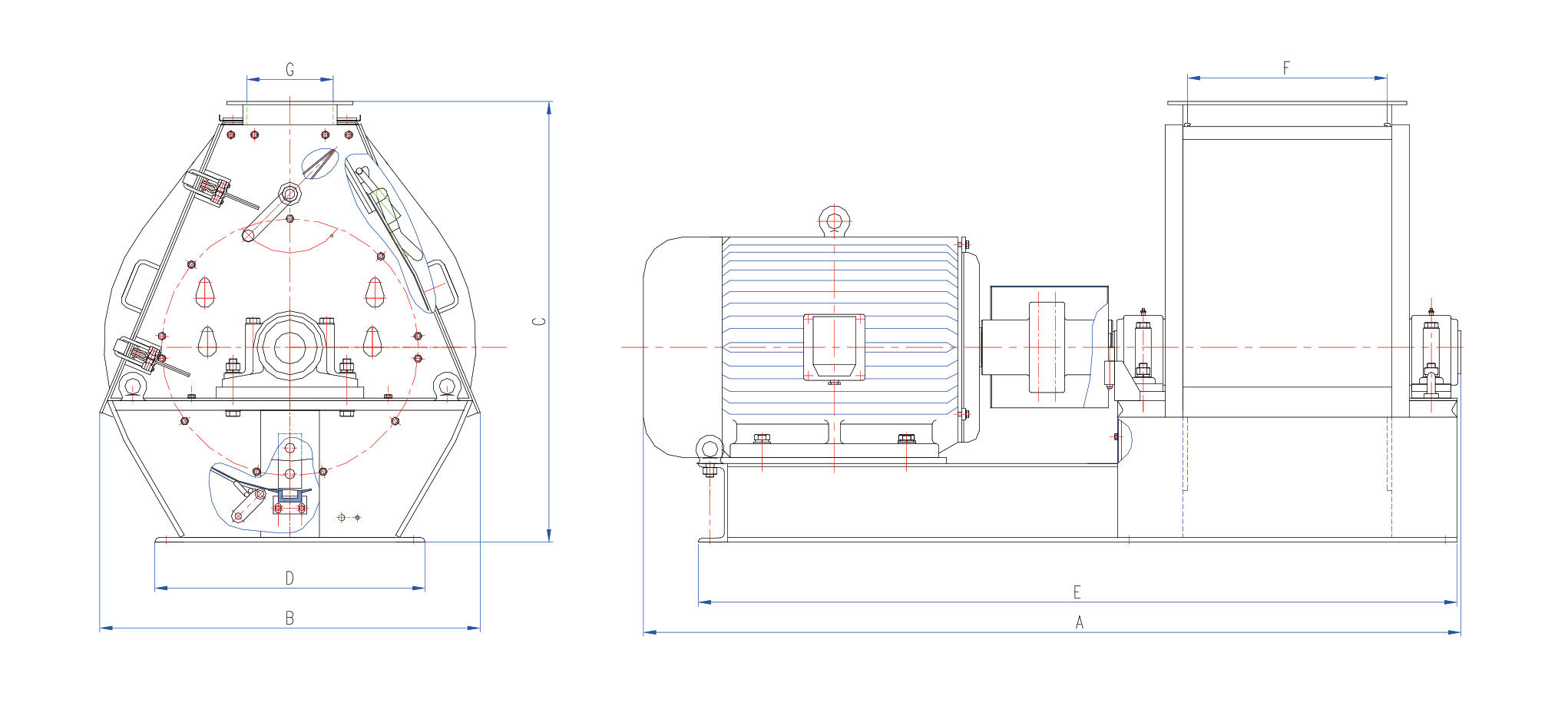

A new generation of horizontal hammer mill that is integrated with the latest technologies worldwide applies to pulverizing and micro pulverizing of a variety of feedstuff. A real “drop-shaped” pulverizing chamber is designed to maximize the effective pulverizing and striking area.the “U-shaped” secondary pulverizing structure greatly improves the pulverizing efficiency.

The embedded rotor disc structure calibrated with high precision dynamic balancing reduces the wear imbalance of the rotor and prolongs the service life; The fully optimized hammer arrangement and the adjustable hammer sieve clearance are used for conversion between ordinary pulverizing and micro pulverizing; SKF / FAG high-speed bearings and welded heavy-duty base are used.

The material guiding direction valve is equipped with a safety device. Belt-type magnetic separation feeder and impeller-type magnetic separation feeder can be equipped optionally according to user requirements.

Note: The capacity index is based on corns pulverized using 2.5mm sieve mesh (the moisture of the raw material is less than 13%).

If automatic load controller is equipped optionally, the pulverizing efficiency will be further improved and guaranteed.