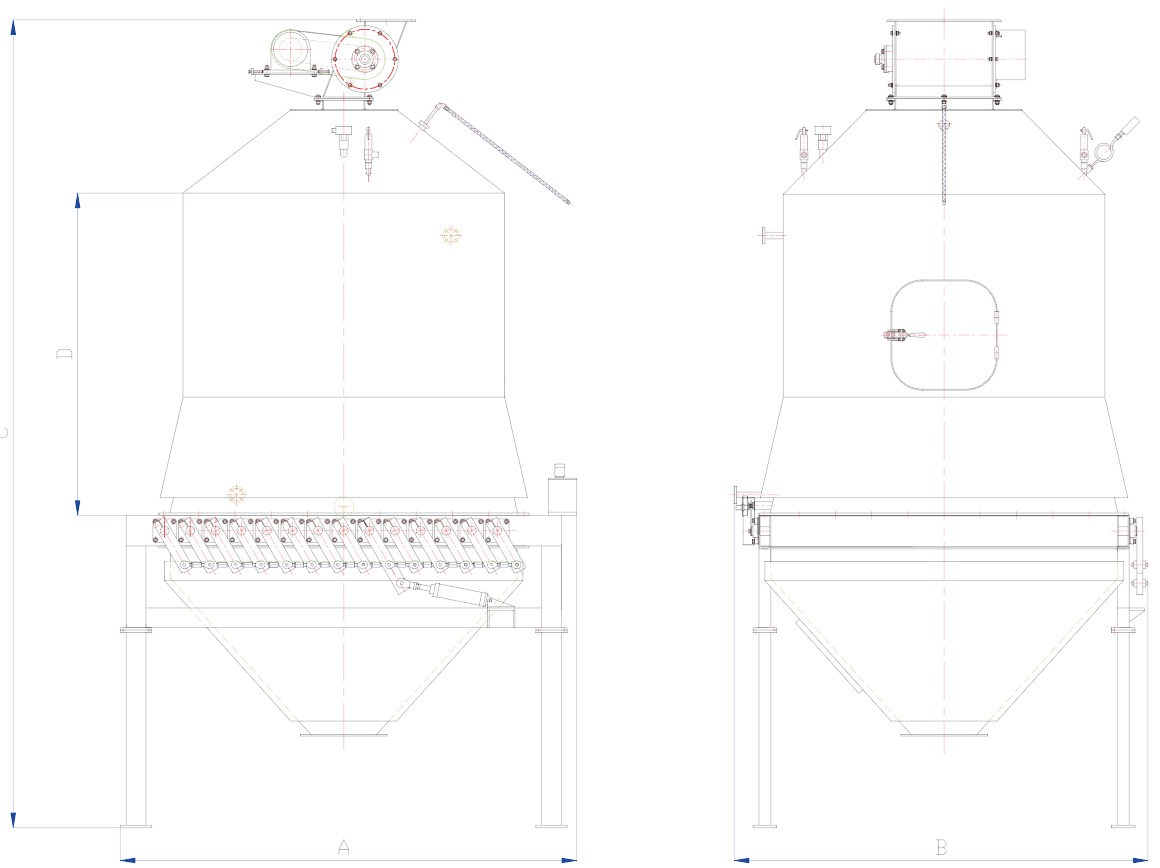

Description

The post-curing machine can promote the full gelatinization of starch, achieving adequate modification of protein and improving the water stability of aquatic feed.

A structure of a steam jacket with an external insulation layer is used and the parts exposed to the material are made of whole stainless steel.

The post curing has an ideal temperature of about 102 to 106 and a processing time of not less than 20 minutes; A structure of rounded inverted cone is used to avoid the uneven distribution of materials, internal arching or local temperature anomalies and other phenomena.

A hydraulic flap-type discharge mechanism is used; The stainless steel eccentric feeding airlock features good air tightness and corrosion resistance;

The temperature control device is used for automatic control of the turning on/off of the internal steam injection and the temperature setting.