Description

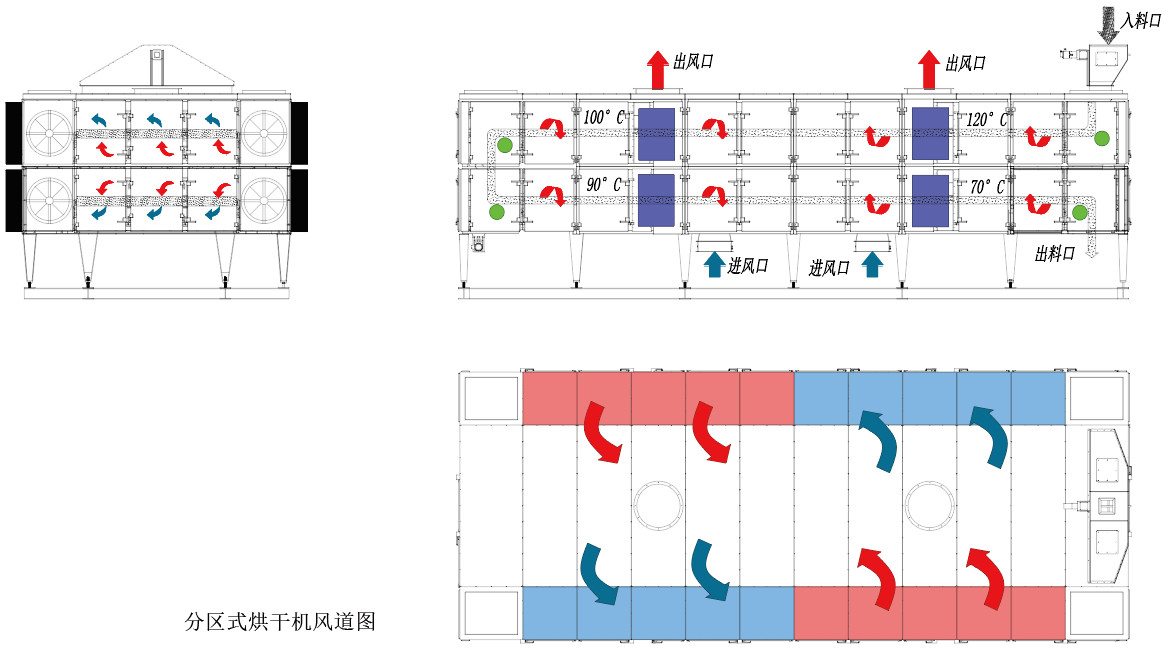

With a modular design, the lengths and directions can be subject to modular combination, meeting different capacity needs and facilitating installation at site, maintenance and product upgrade. With a stainless steel drying chamber, including separate drying areas, in each of which the temperature (50-150 ℃) and airflow direction can be adjusted individually.

The material thickness and drying time of the drying belt can be adjusted continuously. The sieve bed with stainless steel punching plates, the aperture ratio is high, the distributing wind is balanced, and the granule diameters of the products that can be dried have a wide range (0.6-30mm) Setting up a scientific air circulation system ensures not only that the high-humidity saturated air discharges in a timely manner, but also that the surplus thermal energy resources are used effectively, in order to reduce energy consumption and reduce production costs.